How To Make Calcium Carbonate: A Simple Guide For Everyone

Calcium carbonate, a compound found in nature and used in various industries, plays a critical role in everyday life. Whether you're into chemistry, construction, or even baking, understanding how to make calcium carbonate can open up new possibilities. It's like having a superpower in the world of materials science! So, let's dive right in and explore this fascinating topic together.

Picture this: you're in your kitchen, or maybe a lab, and you need calcium carbonate for a project. Where do you start? What are the steps? And most importantly, how can you ensure you're doing it safely and effectively? These are all questions we'll tackle in this article. So, grab your notebook—or maybe a coffee—and let’s get started.

This guide isn’t just for scientists or chemists. It’s for anyone curious about the world of chemistry and materials. By the time you finish reading, you’ll have a solid understanding of how to make calcium carbonate, its uses, and why it matters so much. Sound good? Let’s go!

- Madison Beer Video Rumors The Truth Impact Exposed

- Movierulz Movies Reviews News Fix No Results Errors

What is Calcium Carbonate?

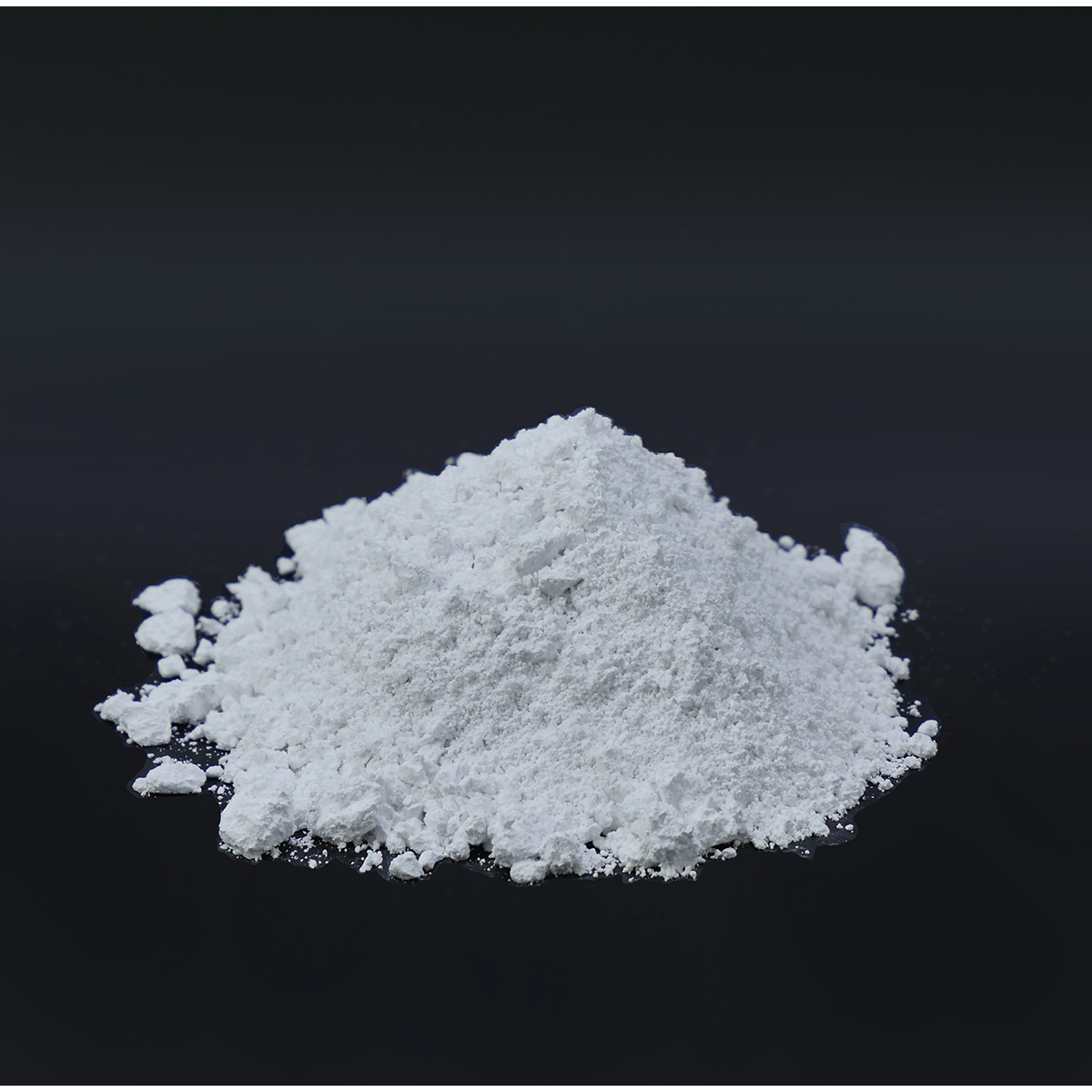

Before we dive into the "how," let's first understand the "what." Calcium carbonate is a chemical compound with the formula CaCO₃. It's one of the most abundant materials on Earth, found in limestone, marble, and chalk. You might not realize it, but you probably encounter calcium carbonate every day. It's in your toothpaste, your supplements, and even your food.

Here’s a quick fact: calcium carbonate makes up around 4% of the Earth's crust. That’s a lot of material! But why is it so important? Well, it has a wide range of applications, from construction to medicine. And that’s exactly why knowing how to make it can be incredibly useful.

Why Is Calcium Carbonate So Important?

Let’s break it down. Calcium carbonate is used in:

- Kannada Movies 2023 Watch Online Top Films Movierulz Update

- Movierulz Kannada 2023 Risks Legal Alternatives

- Construction: As a primary ingredient in cement and concrete.

- Medicine: In antacids to neutralize stomach acid.

- Food: As a dietary supplement for calcium.

- Industry: In the production of glass, paper, and plastics.

It’s like the Swiss Army knife of materials. You can’t beat its versatility. But how does one go about making it? That’s the question we’ll answer next.

How to Make Calcium Carbonate: The Basics

Making calcium carbonate is simpler than you might think. At its core, the process involves reacting calcium with carbon dioxide to form calcium carbonate. But there are several methods you can use, depending on your resources and needs. Let’s explore the most common ones.

Method 1: Using Calcium Chloride and Sodium Carbonate

This is one of the easiest methods for making calcium carbonate at home or in a lab. Here’s how it works:

- Start by dissolving calcium chloride (CaCl₂) in water to create a solution.

- Next, dissolve sodium carbonate (Na₂CO₃) in water to create a second solution.

- Slowly mix the two solutions together. You’ll notice a white precipitate forming. That’s calcium carbonate!

- Filter the mixture to separate the solid calcium carbonate from the liquid.

- Wash and dry the precipitate to get pure calcium carbonate.

Voila! You’ve just made calcium carbonate. Easy, right?

Method 2: Using Calcium Hydroxide and Carbon Dioxide

This method is a bit more hands-on but equally effective. Here’s what you need to do:

- Dissolve calcium hydroxide (Ca(OH)₂) in water to create a lime solution.

- Pass carbon dioxide (CO₂) gas through the solution. You’ll see the solution become cloudy as calcium carbonate forms.

- Filter the mixture to collect the solid calcium carbonate.

- Wash and dry the precipitate for purity.

This method is great if you have access to carbon dioxide, like from a soda can or a CO₂ tank.

Understanding the Chemistry Behind Calcium Carbonate

Now that you know how to make it, let’s talk about the chemistry. Calcium carbonate forms when calcium ions (Ca²⁺) react with carbonate ions (CO₃²⁻). This reaction is called precipitation, and it’s what gives us the solid white powder we all know.

Here’s the chemical equation:

Ca²⁺ + CO₃²⁻ → CaCO₃

Simple, right? But there’s more to it. The conditions under which the reaction occurs can affect the quality and purity of the calcium carbonate. For example, temperature, pH, and concentration all play a role. That’s why it’s important to follow the steps carefully.

Factors Affecting Calcium Carbonate Formation

When making calcium carbonate, keep these factors in mind:

- Temperature: Higher temperatures can speed up the reaction but may also affect the crystal structure.

- pH: The ideal pH for calcium carbonate formation is slightly basic, around 8-9.

- Concentration: Too much reactant can lead to impurities, so it’s best to use the right amounts.

By controlling these factors, you can ensure you get high-quality calcium carbonate every time.

Applications of Calcium Carbonate

Now that you know how to make it, let’s talk about what you can do with it. Calcium carbonate is used in so many industries that it’s hard to list them all. But here are some of the most common applications:

In Construction

Calcium carbonate is a key ingredient in cement and concrete. It acts as a filler and binder, giving these materials their strength and durability. Without calcium carbonate, buildings wouldn’t stand as tall or last as long.

In Medicine

As an antacid, calcium carbonate neutralizes stomach acid and provides relief from heartburn and indigestion. It’s also used as a calcium supplement to support bone health.

In Food

Calcium carbonate is added to food products to fortify them with calcium. It’s also used as a leavening agent in baking, helping dough rise and giving baked goods their fluffy texture.

Safety Precautions When Making Calcium Carbonate

While making calcium carbonate is relatively safe, there are still some precautions you should take:

- Always wear gloves and safety goggles when handling chemicals.

- Work in a well-ventilated area to avoid inhaling any fumes.

- Dispose of waste materials properly to avoid environmental harm.

Remember, safety first. You don’t want to end up with a science experiment gone wrong!

Common Mistakes to Avoid

Here are some common mistakes people make when making calcium carbonate:

- Using too much reactant, leading to impurities.

- Not controlling the pH, resulting in poor-quality product.

- Skipping the washing and drying steps, which can leave behind contaminants.

By avoiding these mistakes, you’ll be well on your way to mastering the art of calcium carbonate production.

Tips for Success

Here are a few tips to help you succeed:

- Use high-quality reagents for the best results.

- Follow the steps carefully and don’t rush the process.

- Experiment with different conditions to see what works best for you.

Remember, practice makes perfect. The more you experiment, the better you’ll get at making calcium carbonate.

Conclusion

Making calcium carbonate is a fascinating process that anyone can learn. Whether you’re a scientist, a student, or just someone curious about the world of chemistry, this guide has given you the tools you need to succeed. From understanding the basics to mastering the techniques, you now have the knowledge to create your own calcium carbonate.

So, what are you waiting for? Grab your lab coat—or maybe just an apron—and get started. And don’t forget to share your results with us in the comments below. We’d love to hear about your experiences!

Table of Contents

- What is Calcium Carbonate?

- Why Is Calcium Carbonate So Important?

- How to Make Calcium Carbonate: The Basics

- Method 1: Using Calcium Chloride and Sodium Carbonate

- Method 2: Using Calcium Hydroxide and Carbon Dioxide

- Understanding the Chemistry Behind Calcium Carbonate

- Factors Affecting Calcium Carbonate Formation

- Applications of Calcium Carbonate

- Safety Precautions When Making Calcium Carbonate

- Common Mistakes to Avoid

- Tips for Success

- Conclusion

- Does Richard Rankin Have A Child The Truth Revealed

- Movierulz Movies Reviews News Fix No Results Errors

Calcium Carbonate Chalk (25KG)

Calcium Carbonate

Calcium Carbonate Global Composites